Versatile and effective

Lift - tilt - rotate - position

- Individual adaptations

- Versatile system options

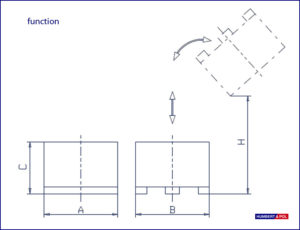

Lifting and tilting devices are used wherever boxes, containers, octabins, barrels, skeleton containers, pallets or stacking containers are to be transported to a desired height and tilted or positioned there with a high degree of functional safety. HUMBERT & POL offers customers individual stations, with which almost all bulk or piece goods can be emptied or arranged.

Lifting and tilting stations

Powerful and robust

HUMBERT & POL lifting and tipping stations are made of high quality steel construction, always designed for the respective payload. Low-wear and operationally reliable components ensure above-average durability. Lifting and dumping heights can be adapted to existing operations and conditions.

HUMBERT & POL lifting and tipping stations are made of high quality steel construction, always designed for the respective payload. Low-wear and operationally reliable components ensure above-average durability. Lifting and dumping heights can be adapted to existing operations and conditions.

Lifting and tilting stations

Customisation

The possibilities for customizing a HUMBERT & POL lift and tilt station, along with the almost unlimited adaptability to specific transport tasks and operational processes, enable its use in many industries.

Lifting and tilting stations

High safety

Our stations are characterized by user-friendliness and high work safety for the operating personnel. A wide range of safety accessories such as protective grids, mechanical or automatic opening and operating locks are available.

Lifting and tilting stations

Special applications & options

Depending on the application and need, these options are also available:

- Mechanical, pneumatic or hydraulic fixing and securing of the containers

- Individual enclosure by grids or light barriers

- Access control

- Alarm messages and signals

- Chain drives, pneumatic or hydraulic drives