Vertical cargo transport > Upward and downward

- Low-wear

- Low maintenance

- Lowest space consumption

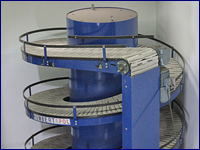

Continuous material transport up or down. Extremely space-saving vertical conveyor technology in column design for unit loads such as buckets, cartons, trays, sacks, canisters and the like. This means maximum efficiency without control effort and with low energy consumption during continuous operation. Conveying speed up to 60 m/min. Can also be operated as a memory.

Spiral conveyor

Advantages at a glance

- Minimum required footprint and easy installation on site

- Continuous or stop-and-go operation

- Only one drive motor necessary

- Automatic tensioning of the conveyor chain by weight load

- Available in standard or stainless steel version

Spiral conveyor

Model variants

![]()

All models also available in mirror image version - Other models on request

Spiral conveyor

Reliable and powerful

Overlapping transport plates also in the web curves ensure safe transport of the piece goods as well as low-wear and low-noise continuous operation.

Spiral conveyor

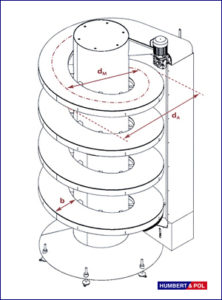

Dimensionally accurate for your general cargo

| B | DM |

DA |

| Panel width | Ø | Ø outside |

| 250 mm | 1300 mm | 1650 mm |

| 400 mm | 1300 mm | 1800 mm |

| 600 mm | 1600 mm | 2300 mm |

Spiral conveyor

Special applications & options

- Double lane design

- Out- and in-feed modules for intermediate levels

- Transfer rollers for the outfeed and infeed area

- Upstream and downstream materials handling equipment such as conveyors, roller conveyors, etc.